System Information of Volvo Penta Engine

- Jun 13, 2018

- 5 min read

Presentation

This installation manual contains information for installing and carrying out function and performance checks on the EMS 2 system (electronic control of the injection system). This instruction manual is intended only for professional use. Read the instructions carefully before starting the installation. If the installation is performed in an incorrect manner, it may cause personal injury or damage to property and machinery. Ask your Volvo Penta dealer for help if there is anything in this manual that you do not understand or are uncertain about.

Working methods

The work must be performed by a Volvo Penta workshop or other authorized, well-equipped workshop by qualified and experienced personnel. These instructions refer to such personnel as fitters. This installation manual is intended to be used together with the operator's manual for the engine concerned. The fitter is responsible for ensuring that the system functions in accordance with these installation instructions. Volvo Penta disclaims all responsibility for injury to persons or damage to property that may occur as a result of not following the installation guidelines, or for work carried out by unqualified personnel.

Set out below is a summary of the risks and safety measures that must be observed or carried out when the EVC system is installed and calibrated.

Disconnect connectors to the EMS control unit before any arc welding is carried out. Turn the current off at the main switches. Undo and remove the control unit connectors. Reconnect the EMS 2 control unit connectors once welding is completed and the welding equipment has been removed.

Take care to keep clear of the engine's moving parts during functional checks and operations. There is a risk for personal injury when approaching a running engine. Remember that loose clothing and long hair can fasten in rotating parts and cause serious injury.

Never work on an engine that is suspended from lifting gear (a crane or similar).

The engine must not be run in areas where there are explosive materials or gases.

Only start the engine in well-ventilated places. If the engine is operated in an enclosed space, make sure that there is sufficient ventilation to remove the exhaust gases and crankcase fumes from the workplace.

Never expose battery compartments to open flames or electrical sparks. Never smoke in the vicinity of the batteries. Batteries generate hydrogen gas during charging, which can combine with air to form an explosive mixture. This gas is highly flammable and explosive. Incorrect connection of the batteries may cause sparks that in turn cause an explosion resulting in damage. Do not switch battery connections when attempting to start the engine (risk for sparks) and do not lean over the batteries. Refer to the instructions in the engine operator's manual.

Make sure that the positive (+) and negative (-) battery cables are correctly connected to the corresponding battery terminals. Serious damage may be caused to the electrical equipment if the cables are transposed. Refer to the wiring diagram in the engine operator's manual.

Always wear eye protection when charging or handling the batteries. Battery electrolyte contains sulfuric acid which is highly corrosive. If electrolyte comes into contact with bare skin, wash the exposed area immediately with copious amounts of clean water and soap. Then seek medical attention. If you get battery electrolyte in your eyes, flush them immediately (preferably using eye wash equipment) with copious amounts of clean water. Then seek immediate medical attention.

System Information

EMS

Engine control system

EMS 2 stands for “Engine Management System” and is an electronic system with CAN communications (Controller Area Network) for control of diesel engines. The system has been developed by Volvo Penta and includes fuel control and diagnosis function. The system consists of a control module, six unit injectors, a number of sensors that supply the control module with measurements, sockets for diagnosis and functional checks. The engine can be connected to a communication interface comprising a CAN-link and a serial link.

CAN (Controller Area Network)

The CAN J1939 link handles all communication between the engine control module EMS 2 and the CIU, in addition to the diagnostics that are handled by the so called J1708/J1587 link. The CAN link is much faster than the J1708/J1587 link. The CAN link has been prepared to connect to other components with SAE J1939 protocol such as instrument panels and transmissions. If, for some reason, a fault develops on the CAN link, signals for the rpm-potentiometer and the start and stop knobs are taken over by the J1708/J1587 link. However, instrument and indicator lamps are completely turned off. If a fault occurs on both links, GE engines maintain engine speed, while VE engines go to idle. The only way to shut off the engine in this case is to use the auxiliary stop (AUX-STOP) placed on the engine’s left side.

CIU (Control Interface Unit)

The CIU is a “translator” between the CAN bus and the customer’s own control panel. This unit has two serial communication links, one fast and one slow. The fast one is a CAN link that features a bus speed of 250 Kbit/ s. All data regarding instruments, indicator lamps, contacts and potentiometers are controlled by this bus. The slower J1708/J1587 link handles diagnostic information for, among other things, the flashing code. The diagnosis tool VODIA also uses the J1708/J1587 link to communicate with the system.

Fuel control

The engine’s fuel requirement is analyzed up to 100 times per second (depending on engine rpm). The engine’s injection amount and injection timing is controlled electronically via fuel valves on the unit injectors. This means that the engine always receives the correct volume of fuel in all operating conditions, which offers lower fuel consumption, minimal exhaust emissions etc. The control module checks and controls the unit injectors so that the correct amount of fuel is injected into each cylinder. It calculates and sets the injection angle. The control is primarily performed using the speed sensors and the combined sensor for boost pressure/charge air temperature. The control module affects the unit injectors via an electronic signal to the unit injectors’ electromagnetic fuel valve, which can open and close. When the fuel valve is open, fuel flows through the unit injector hole and out through the fuel channel. Fuel is not sprayed into the cylinder in this position. When the fuel valve closes, pressure starts to build from the unit injector’s mechanically operated pump plunger. When sufficient pressure has developed, fuel is injected into the cylinder via the unit injector’s injector section. The fuel valve is re-opened and pressure in the unit injector decreases at the same time as the fuel injection to the cylinder stops. In order to determine when the fuel valve shall open or close, the control module has access to signals from sensors and switch contacts.

Calculating fuel quantity

The amount of fuel that is sprayed into a cylinder is calculated by the control module. The calculation determines the time that the fuel valve is closed (when the fuel valve is closed fuel is sprayed into the cylinder). The parameters controlling injected amount of fuel

are:

• Requested engine speed

• Motor protector

• Temperature

• Boost air pressure

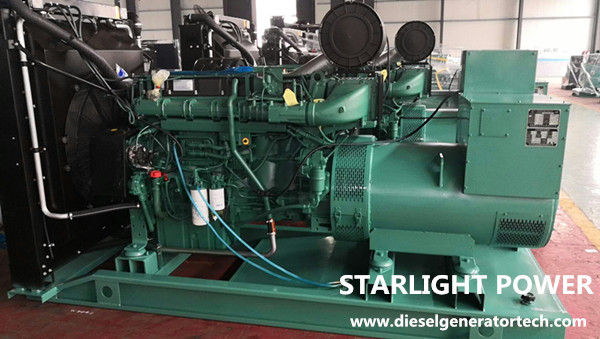

We can provide 68KW to 600KW Volvo Power Generation.

Comments